The first of these is what is known as the static loading gauge. This can be thought of as the aperture through which all railway vehicles must be able to pass when running slowly on straight track. In practice, tracks are curved and railway vehicles cut across and project beyond the chord of a circle. Within the wheelbase, the distance cut across the curve is sometimes known as the overthrow and the projection beyond the wheelbase is referred to as the kick-out. A long vehicle cuts off more of a chord than a short one (diagram below) Taking curvature into consideration in this way leads to the concept of the dynamic loading gauge, which, however, also takes account of the suspension characteristics of the vehicle.

The diagram shows how gaps between the platform and the train will arise differently at concave and convex platform faces, and that these gaps can be minimised by keeping doorways as close as possible to bogie centres.

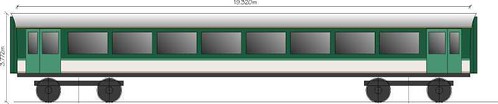

Following the nationalisation of Britain's railways in 1948, a survey of the infrastructure was made and an optimum loading gauge established for passenger vehicles. This was known as the C1 loading gauge and eventually it became possible for vehicles built to this gauge to operate over almost the entire system. The C1 loading gauge applied to vehicles of a nominal 20 metre width with bogies at 14.174 metre centres, of which the first were the Mark 1 fleet.

These (above) were characterised by curved bodysides with the width reducing to cantrail level (where the roof joins the bodyside)

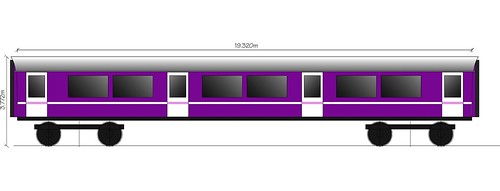

Vehicles to a similar length are still being built, but all of them have two pairs of bi-parting doors at the 1:3/2:3 position. (below)

This divides the vehicle into three saloons, one of four bays in the middle and two of two bays at each end. This is not a particularly satisfactory arrangement. If the vehicle is a monocoque construction, then the large door apertures break into the structure at the worst possible place from the point of view of integrity. Substantial reinforcement is then required around these openings.

The division into three saloons also imposes limitations on the alternative seat layouts that can be accommodated, because the small end compartments can only be used for four rows of seats (or three and a driver's cab) or some special purposes such as a wheelchair and toilet area. The third drawback is that having just two sets of doors per vehicle leads to passengers bunching round doors at stations, which extends station dwell times. The fourth drawback is that it would be inconvenient to fit internal vestibule doors, so that passengers sitting inside are exposed to cold air in the winter when the doors are open, and there is a heavy load on the heating and ventilation system during hot and cold weather.

What are the alternatives? 20 metre long vehicles are used for two types of service. One is for long distance commuting, for example, South Coast inter city. For such routes, an end-door configuration would be more suitable, provided that attention was paid to the detailed design of the doorway and the space immediately inside, with sufficient vestibule and circulation space for passengers to move down inside the car. Otherwise, station dwell times will be too long.

The diagram shows a ten bay vehicle, of which the two end bays are vestibules with wide doorways. It would have internal doors between vestibule and saloon, with the aim of improving passenger comfort and reducing the work required of the heating and ventilation system. Such a configuration would not be suitable for rush hour congestion. An alternative with four single doors would be. Having four doors instead of the standard 1:3/2:3 double-door configuration ought to reduce station dwell time. This is shown below. Each vestibule would occupy a full bay and be provided with space for luggage and perch-type seating. Such a train would be suitable for the inner sections of Thameslink and probably Crossrail also, provided that stations do not have sharply curved platforms.

If higher traffic densities are to be handled, then trains need to have either three or more sets of double doors or two sets of double doors and single doorways at each end, the standard on tube LUL stock.

Inter city vehicles

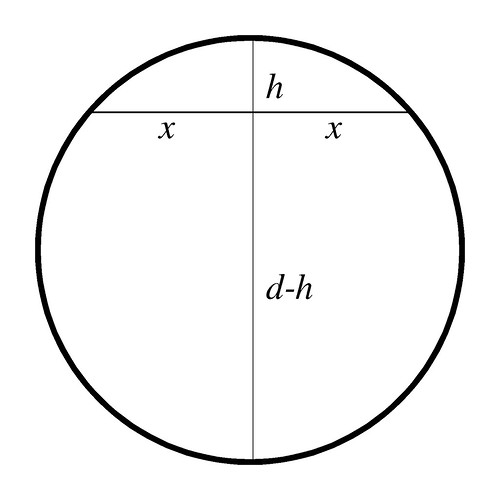

Finally, there is the matter of longer inter city vehicles. Due to the overthrow on curves, the width of a vehicle longer than 20 metres must be reduced by an amount proportional to the square of the distance between bogie centres. This is based on the formula x squared equals h*(d-h), where x is half the length of a chord and d is the diameter. h is the distance cut off by the chord. (diagram below)

A vehicle 20 metres long can be built to the full permitted width of 2.82 metres. Longer vehicles were introduced in the 1970s, with the mark 3 design. Based on a track curvature of 200 metres, a 23 metre vehicle must be 8 cm narrower (2.74), which is the same width as a mark 1 vehicle due to the projection of door handles etc on the 1940s-designed stock. However, a vehicle of intermediate length could be built to a width of 2.79 metres, losing just 3 cm from the maximum permitted width, whilst gaining an extra bay compared with a mark 1 coach.

The photographs at the bottom, which shows the Swedish X2000 tilting train with stainless corrugated bodyshell, and the Alstom Adelante, give an idea of what is envisaged. Such vehicles are an appropriate choice for locomotive hauled or electric multiple unit inter-city trains, such as we are likely to see now that the IEP project is abandoned.

Stainless steel bodyshells (below, lower) would be worth considering on account of their extreme long life and low maintenance requirements.

Wheelchair access and more...

Wheelchair access toilets have to date not been particularly well integrated into the vehicle interior layout. One issue is that the size of the module does not fit with a centre aisle seating layout. Another is that there is a need to provide access to toilets from the entrance vestibule rather than from the passenger saloon to prevent annoyance from bad odours. With this in mind, it is worth considering if wheelchair access toilets should not be associated with other facilities which require an off-centre gangway, such as catering areas, first class compartments and luggage/cycle areas. It would also be worth considering whether toilets should be provided in every vehicle. It might be advantageous to concentrate toilet facilities in fewer vehicles, to avoid the need for plumbing in every coach; this may create the opportunity to offer additional facilities such as showers for passengers' use.

The central toilet idea is interesting, though it may produce more 'toilet seats' as you mention later on - assuming a dividing wall is incorporated that would make two smaller compartments - which on the surface sounds like quite a pleasant environment for longer distance journeys - neither too small or too big.

ReplyDeleteHaving two types of coaches - one non-toilet - the other with more extensive facilities seems a more likely idea - possibly if a 'bay and a half' is used then this could provide two small toilets+basin (lesser part of off centre) and one large facility - suitable for wheelchairs + some extra room. This would put a toilet at the maximum of one coach in either direction - but at nearly two coaches if you walk in the wrong direction.

As to loading gauges - if it happens that a new line is built to a broader loading gauge then wouldn't it be possible to retrofit selected older coaches with hydraulic(?) extensible steps (or small ramps) for the platforms - I can't see any technical reason why this wouldn't be workable and do-able - I would guess that the additional weight should be a few dozen kilograms (200kg max for a 'cast iron' one) - the purpose being just to stop passengers falling through the gap.

For true metros I can't think of many options due to the necessity of lots of doors. Curiously I've found travelling on trains of such plans quite nice in a general sense - the rows of seats or bays in a Mk3 always seemed a bit "sit there and stay there" whilst the bus-style seats in some coaches give a much less restricted travelling experience (both physically and visually). The lack of a headrest can be annoying when tired (or in a crash no doubt!)

I've wondered about how to get the best of both - whilst seats in the Mk3s etc are comfortable - I find them a heavy in appearance (the arm rests appear to be forged from steel) - surely it must be possible the make a lighter, thinner seat that is as comfortable, and just as safe.

Compare this picked image http://www.flickr.com/photos/94376402@N00/444904458/ with the depth of of mk3 seat (just an exaggerated example not a final design - I know british people are a lot fatter than japanese)

Thanks for those comments. There is nothing new about centre toilets. Some LNER stock had that layout and then it turned up on BR hauled and EMU stock. Of course the toilets need to be on either side of a centre corridor with doors between the corridor and the saloons, which was the arrangement.

ReplyDeleteHigh headrests are a safety requirement now. Retractable steps are commonplace.